1. Small-module Tooth Profile DesignThe spur gear slew drive adopts an optimized small-module tooth profile design. Compared with traditional large-module gears, small-module gears feature smaller tooth pitches and a greater number of teeth, enabling tighter meshing during transmission and minimizing transmission backlash to an extremely narrow range. This structural design enhances the precision of the transmission system, allowing for accurate power transmission to ensure the printing nozzle moves smoothly along the preset path, and effectively avoiding printing deviations caused by transmission backlash.

2. Precision Gear Grinding ProcessBuilding on the small-module design, the spur gear slew drive is manufactured with a gear grinding process, where the gear surfaces are finely polished using professional gear grinding equipment. This process significantly improves gear surface finish and tooth profile accuracy, resulting in higher meshing overlap ratio and smoother transmission performance. The spur gear slew drive processed by gear grinding achieves a unidirectional positioning accuracy of 0.04°, which can precisely control the moving track of the printing nozzle and ensure uniform printing layer thickness.

3. In the future, the spur gear slew drive will continue to support the development of construction 3D printing technology toward higher precision, higher efficiency and larger-scale applications, driving the intelligent transformation of the construction industry.

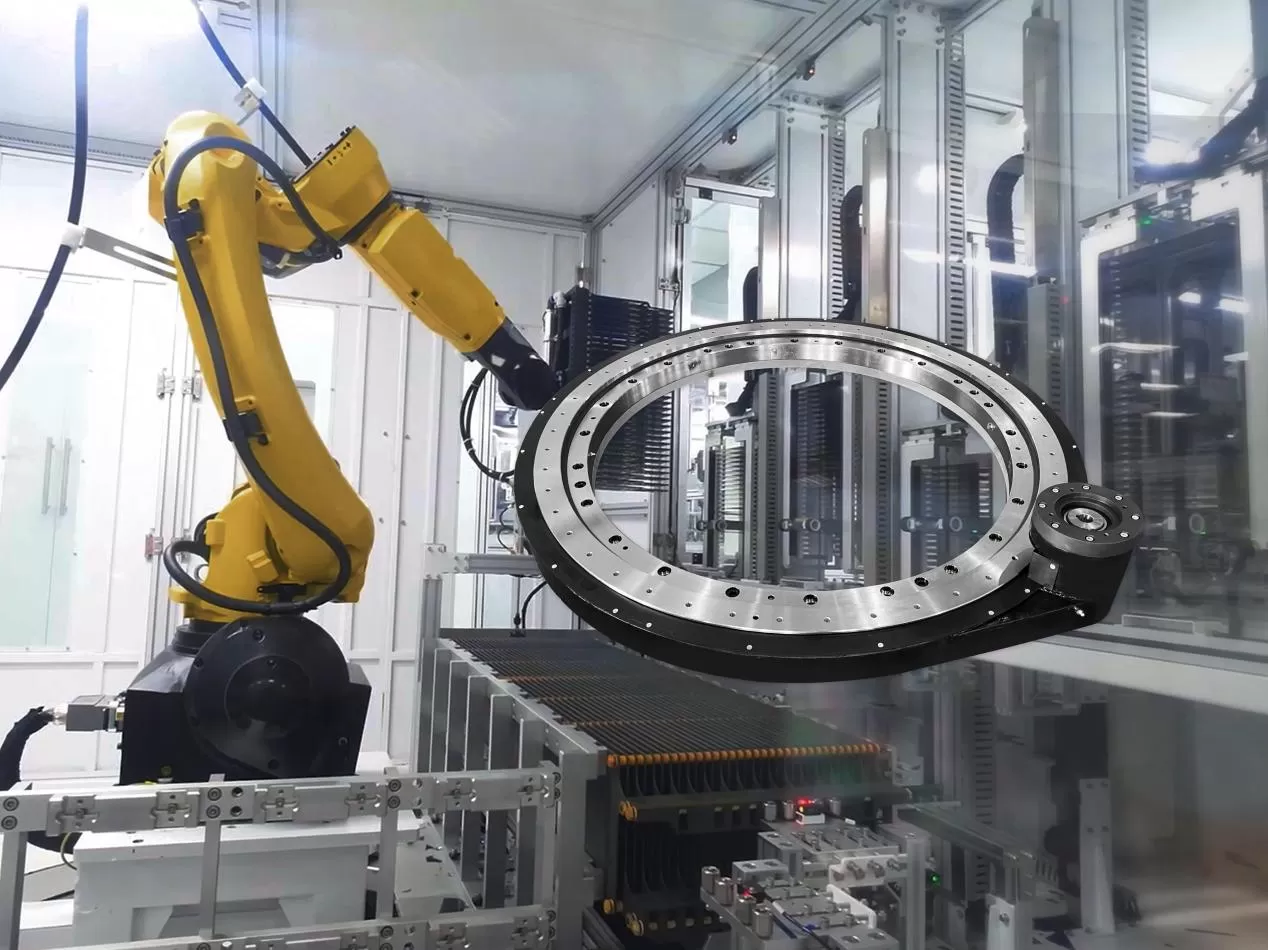

In semiconductor packaging and testing lines, the die insertion machine is a key device that enables precise alignment between chips and carriers. Its operational accuracy and speed directly determine the yield rate of chip packaging and the efficiency of the production line.

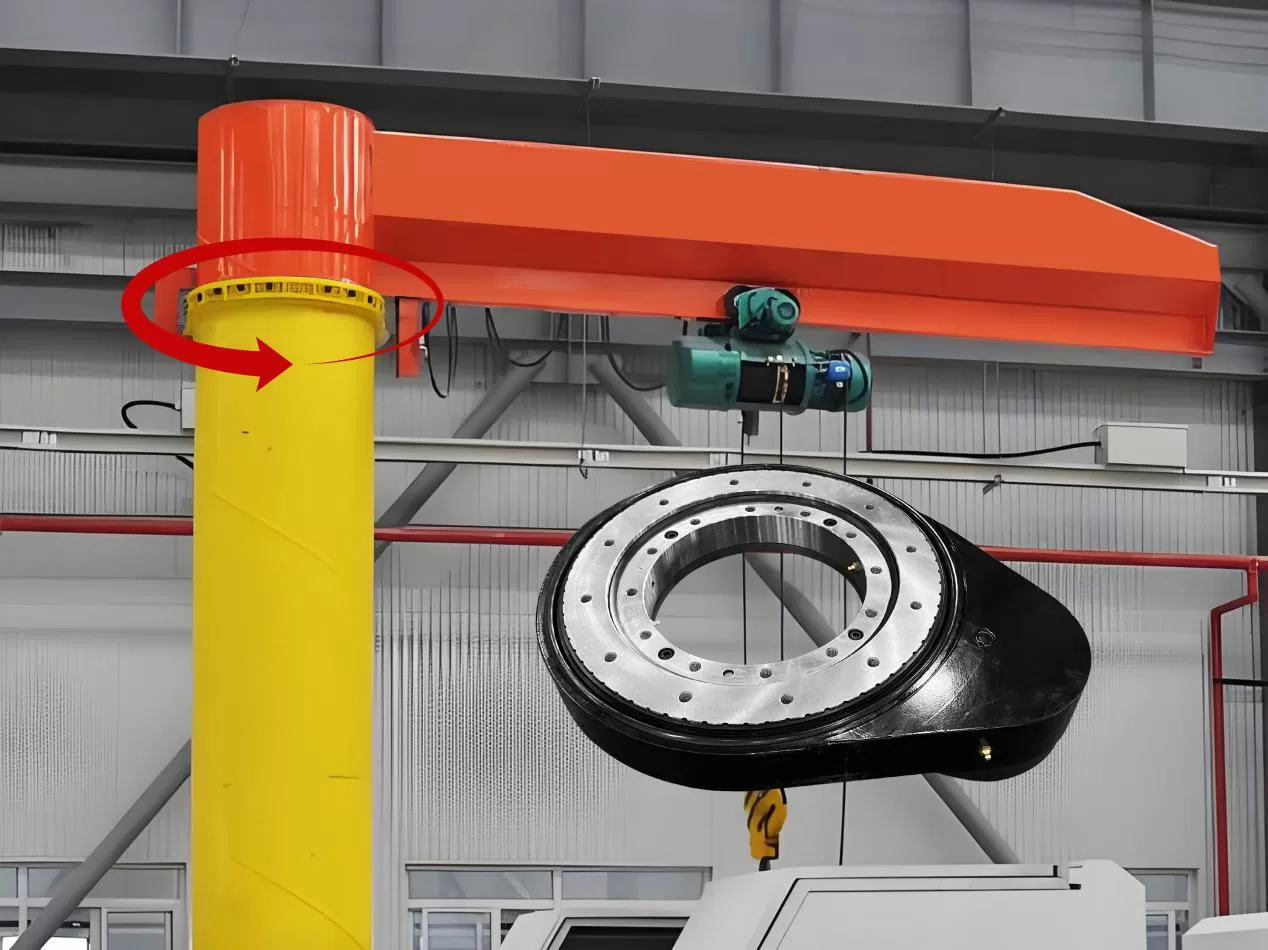

In scenarios such as workshop material handling and equipment maintenance, the stable operation of jib cranes is directly related to lifting safety and operational efficiency — and the key to supporting the precise and reliable rotation of their boom is the spur gear slew drive system integrated into the base.

The spur gear slew drive adopts a precision tooth profile design combined with a gear grinding process, with the transmission backlash controlled within 0.02 mm. When integrated with the steering mechanism of the drive wheel, it enables the AGV to achieve a steering accuracy of ±0.5° — even in narrow passages, the AGV can travel precisely along the preset path, avoiding frame collisions and path deviations.

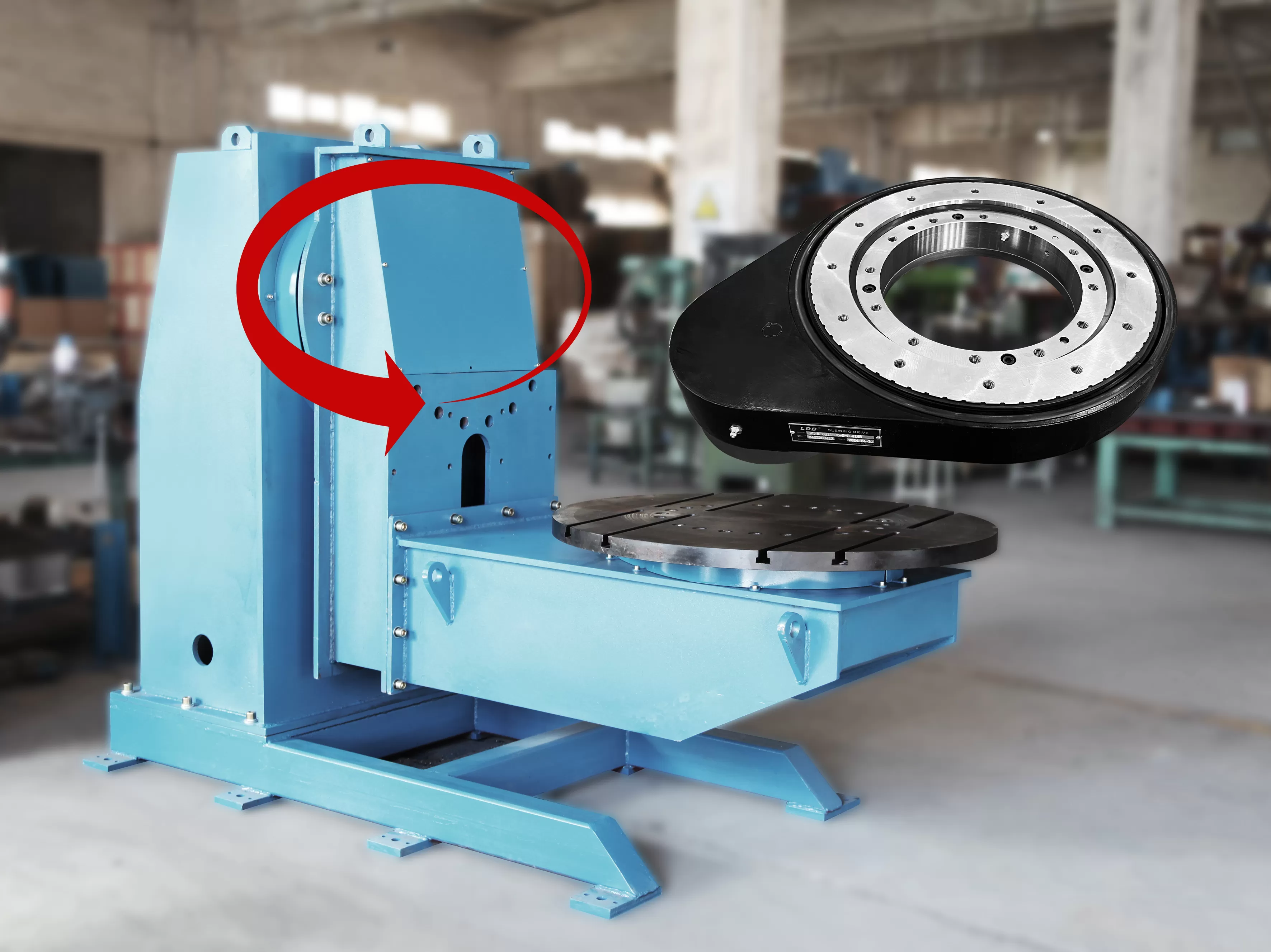

In the field of precision mechanical processing, the positioner is a key auxiliary device for achieving multi-face workpiece machining and improving processing efficiency. Its tilting accuracy, load-bearing capacity, and operational stability directly determine the machining accuracy of workpieces and the continuous operation efficiency of production lines.

This spur gear slew drive is manufactured from high-strength alloy materials, with its core components—the raceway and gear teeth—both treated with a professional quenching process. After quenching and strengthening, the hardness and wear resistance of the raceway are significantly enhanced. Even under the harsh working condition of high overturning load, it can still maintain excellent operational stability, providing a solid guarantee for the safety and reliability of lifting operations.

Chat Online

Get A Quote

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.