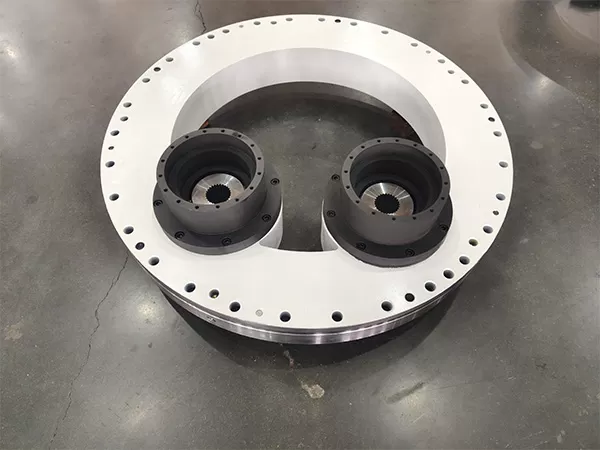

A flanged slewing bearing is a variant of traditional slewing rings that features a flange structure on either the inner or outer ring. This design enables more convenient installation by eliminating the need for a separate mounting plate or housing support.

Compact, lightweight, and easy to align, flanged slewing bearings are ideal for applications with space constraints or strict mounting precision requirements. They are commonly used in packaging equipment, robotic arms, small cranes, rotating displays, and automated guided vehicles (AGVs).

Flanged designs allow for direct bolt-on mounting to a surface or housing. This reduces the need for support rings, minimizes alignment error, and shortens assembly time.

With fewer components and a unified load-bearing surface, flanged slewing bearings contribute to overall space savings. This is critical in compact systems like AGVs, medical imaging tables, and miniaturized automation lines.

Despite their slim form, flanged slewing bearings support:

Axial loads (vertical pressure)

Radial loads (horizontal forces)

Tilting moments (overturning torque)

Depending on raceway and ball arrangement, they can deliver precise, high-stiffness rotation under demanding conditions.

Reduced components mean lower material and labor costs. Maintenance is simpler and access is easier, making flanged designs more budget-friendly over the long term.

A Custom Slew Drive is a compact, highly integrated mechanical system that provides precise, high-torque rotational movement. It is an all-in-one unit that combines a slewing bearing (a large-diameter rolling-element bearing) with a worm gear mechanism, a sealing system, and often a built-in motor and hydraulic or electric brakes.

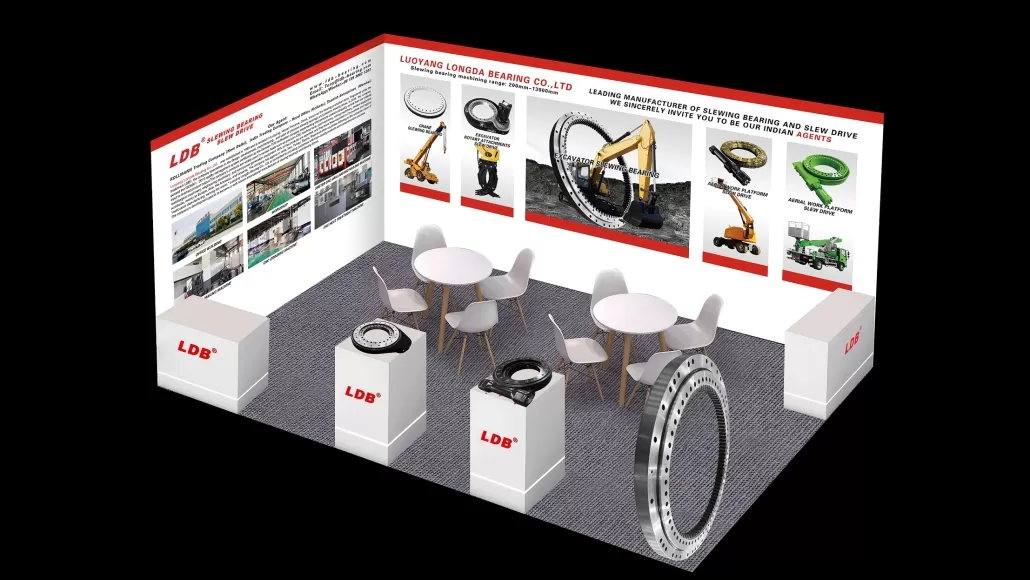

When the eyes of the global industrial sector focus on the core stage of the international exhibition, an enterprise from Luoyang, the “Hometown of Bearings” in China, is stunning the audience with its exquisite craftsmanship and innovative strength

bauma Germany, the world’s top construction machinery event, kicked off in Munich. Luoyang LDB Bearing Co., Ltd. (LDB Bearing) made a grand appearance with its full range of core products and innovative solutions. On the 614,000-square-meter global stage, the company showcased the technical strength and global layout of Chinese bearing enterprises to exhibitors and professional visitors from 57 countries and more than 3,500 enterprises worldwide.

As an enterprise focusing on the R&D and manufacturing of key components for construction machinery, Luoyang Longda Bearing has always been committed to providing high-performance and highly reliable products for global customers. At this expo, we will focus on showcasing the following core product series

Chat Online

Get A Quote

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.