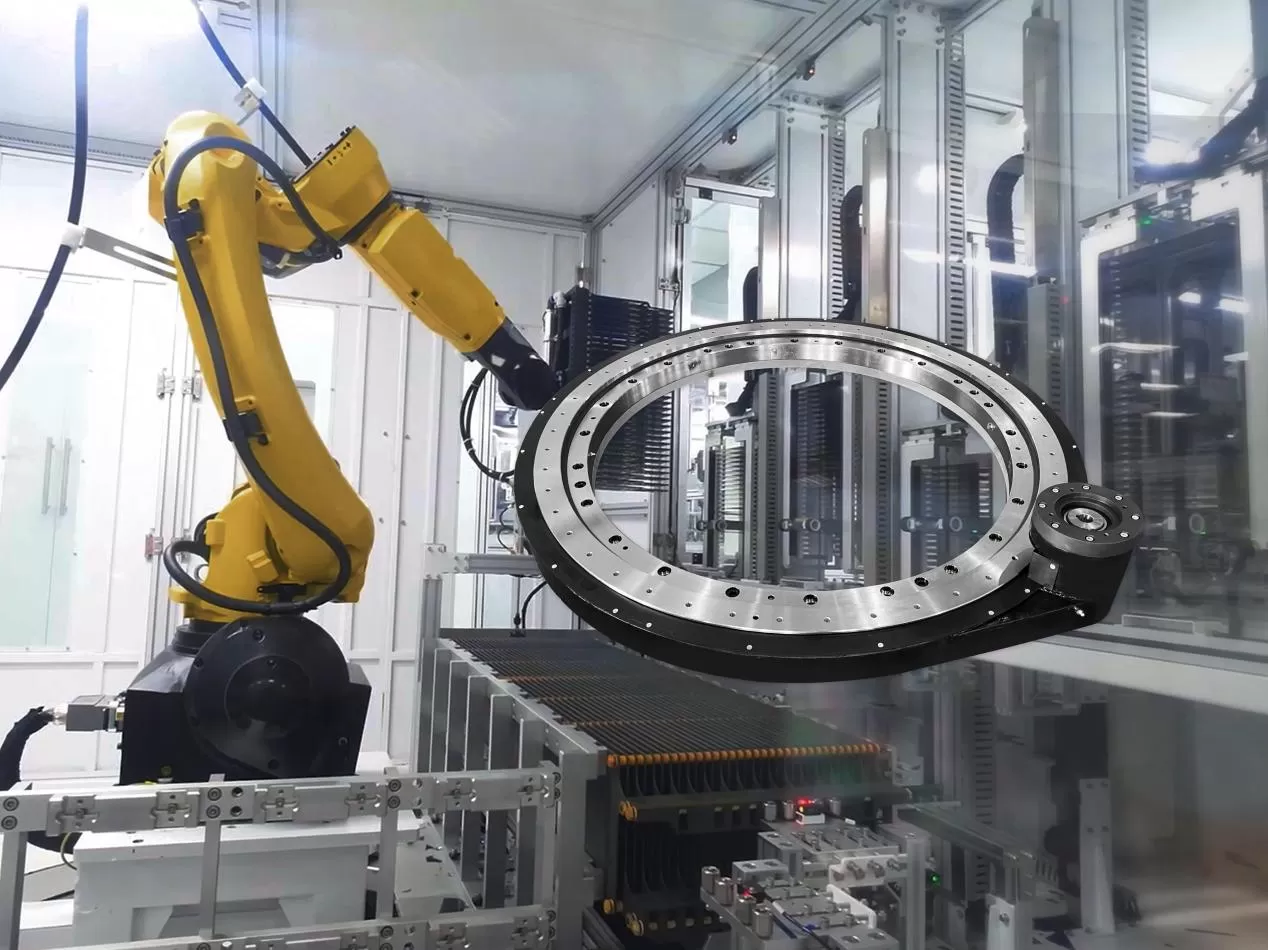

In production lines of industries such as warehousing and logistics, and food processing, the efficient and precise operation of palletizers directly determines cargo turnover efficiency — and the core that supports the flexible and stable rotation of palletizer robotic arms is exactly the spur gear slew drive system mounted on their bases. This transmission component that integrates "high protection, compact size, and high precision" is emerging as a key adaptive solution for palletizers to reduce costs and improve efficiency.

The spur gear slew drive applied to palletizer bases addresses on-site needs directly with four core advantages:

1. Fully Sealed & High Protection: Adapting to Complex Workshop EnvironmentsIt adopts a fully enclosed housing design with a maximum protection rating of IP53, which can effectively isolate workshop dust and slight moisture intrusion. Even in dusty production lines such as flour processing and chemical fertilizer packaging, it can operate stably for a long time, significantly reducing maintenance frequency.

2. High Integration & Compact Size: Saving Production Line Layout SpaceThe integrated design greatly reduces the space occupied by the transmission system. Compared with the traditional drive method of slewing bearing plus pinion, its volume is reduced by about 30%. It can adapt to the compact layout at the end of the production line and can be deployed without the need to expand the operation area additionally.

3.High Rotational Speed + High Precision: Improving Palletizing Operation EfficiencyIt can reach a maximum rotational speed of 20 rpm under light-load conditions. In addition, with its own unidirectional positioning accuracy of 0.04° and the matching encoder, it achieves minimal reciprocating positioning error — which not only ensures the efficiency of the robotic arm in quickly switching pallet positions, but also enables precise alignment of goods, avoiding loose pallet stacking and improving palletizing stability.

In semiconductor packaging and testing lines, the die insertion machine is a key device that enables precise alignment between chips and carriers. Its operational accuracy and speed directly determine the yield rate of chip packaging and the efficiency of the production line.

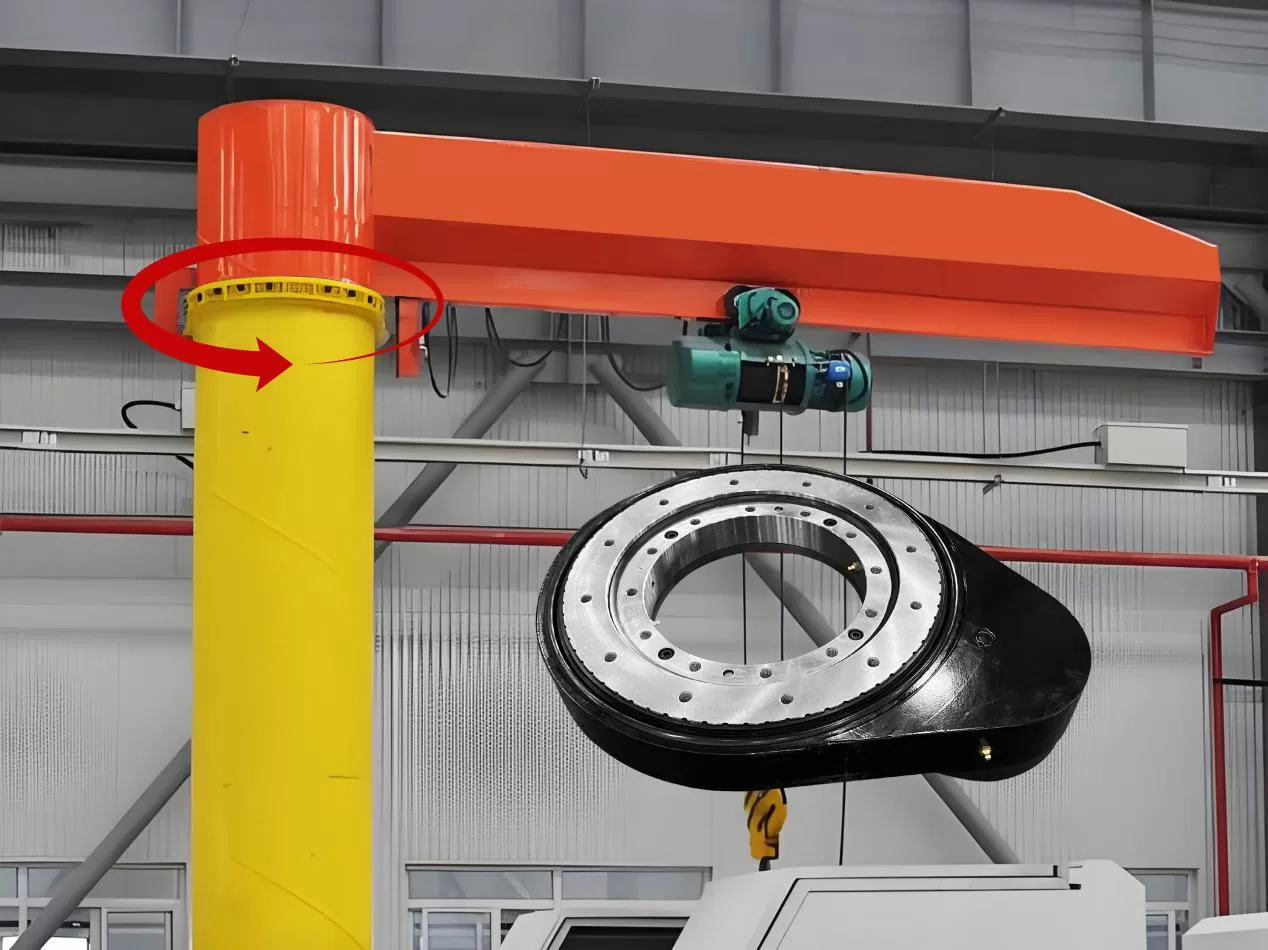

In scenarios such as workshop material handling and equipment maintenance, the stable operation of jib cranes is directly related to lifting safety and operational efficiency — and the key to supporting the precise and reliable rotation of their boom is the spur gear slew drive system integrated into the base.

The spur gear slew drive adopts a precision tooth profile design combined with a gear grinding process, with the transmission backlash controlled within 0.02 mm. When integrated with the steering mechanism of the drive wheel, it enables the AGV to achieve a steering accuracy of ±0.5° — even in narrow passages, the AGV can travel precisely along the preset path, avoiding frame collisions and path deviations.

Small-module Tooth Profile DesignThe spur gear slew drive adopts an optimized small-module tooth profile design. Compared with traditional large-module gears, small-module gears feature smaller tooth pitches and a greater number of teeth, enabling tighter meshing during transmission and minimizing transmission backlash to an extremely narrow range.

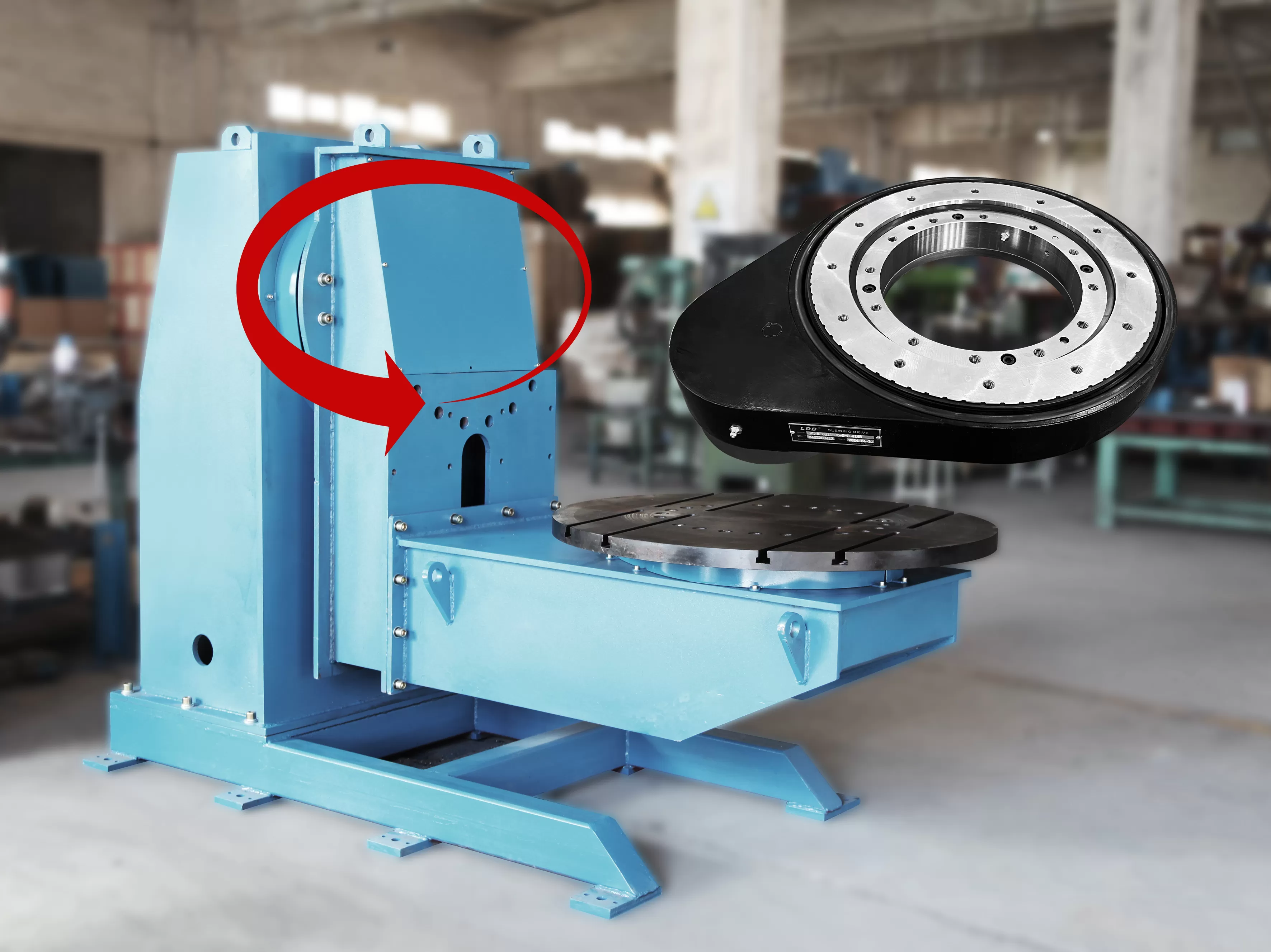

In the field of precision mechanical processing, the positioner is a key auxiliary device for achieving multi-face workpiece machining and improving processing efficiency. Its tilting accuracy, load-bearing capacity, and operational stability directly determine the machining accuracy of workpieces and the continuous operation efficiency of production lines.

Chat Online

Get A Quote

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.