PRODUCT CATEGORY

About LDB

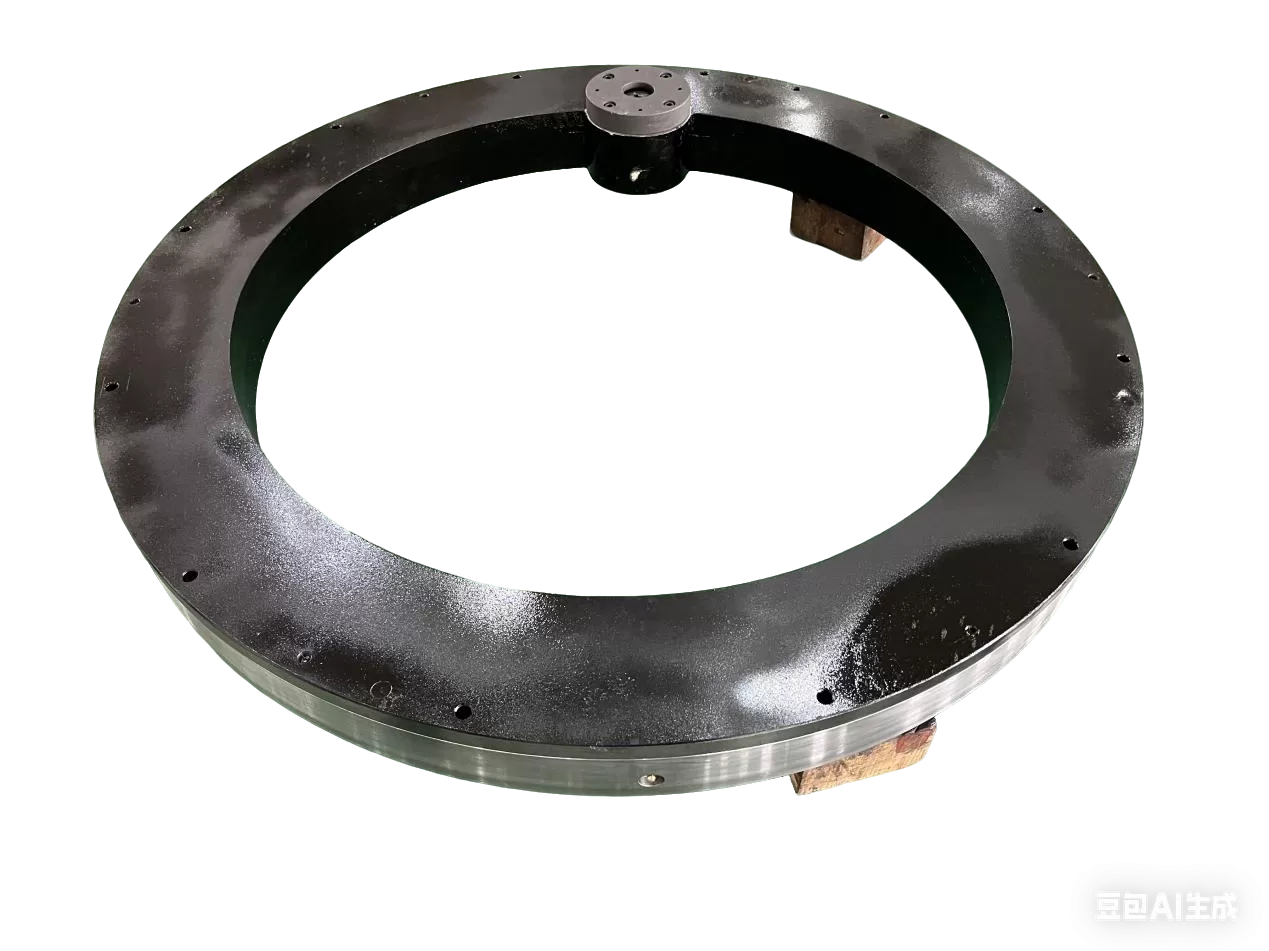

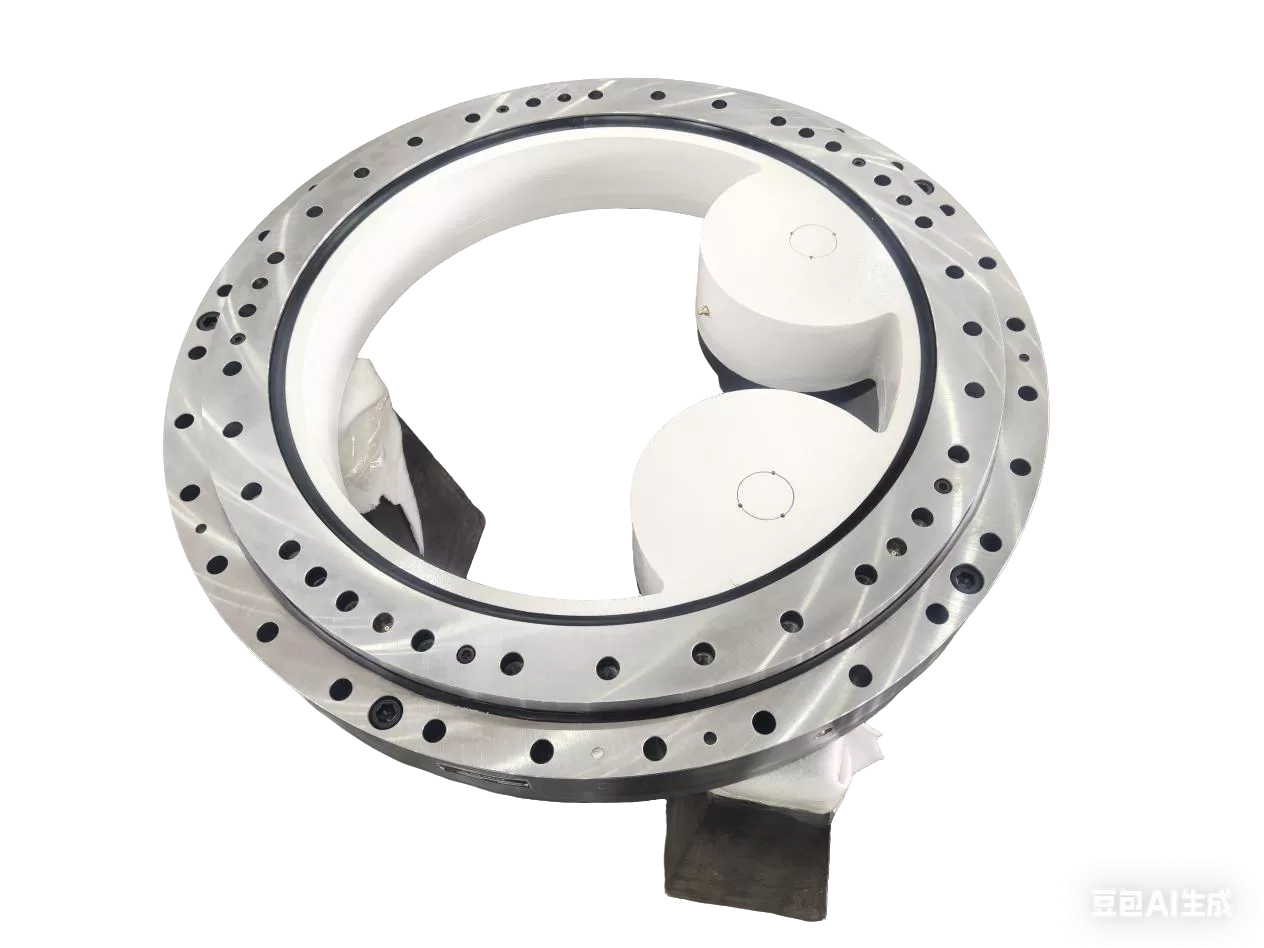

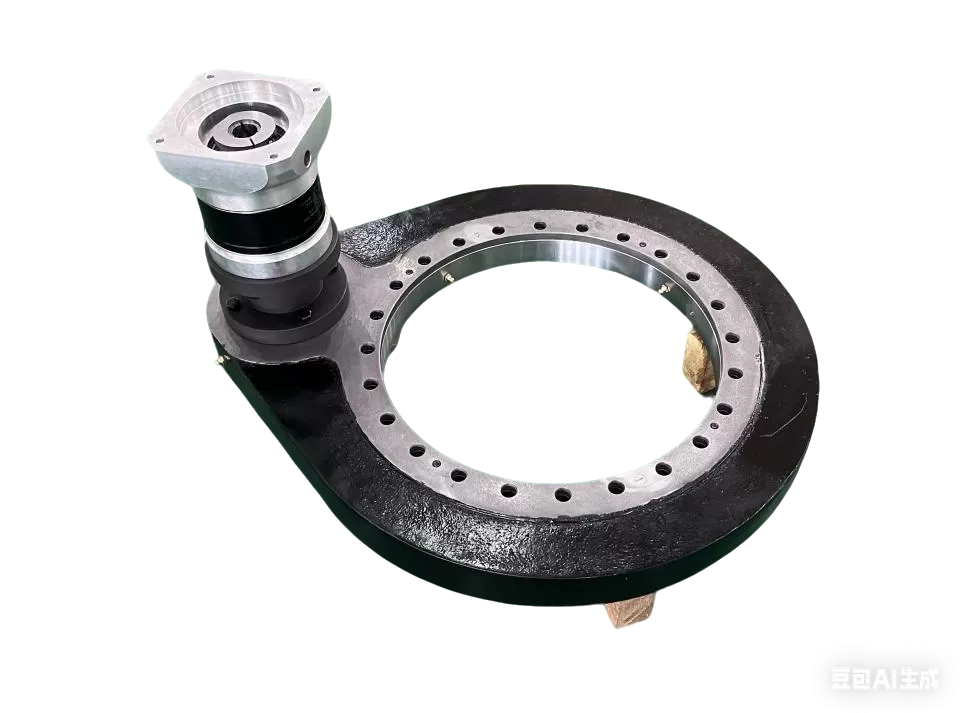

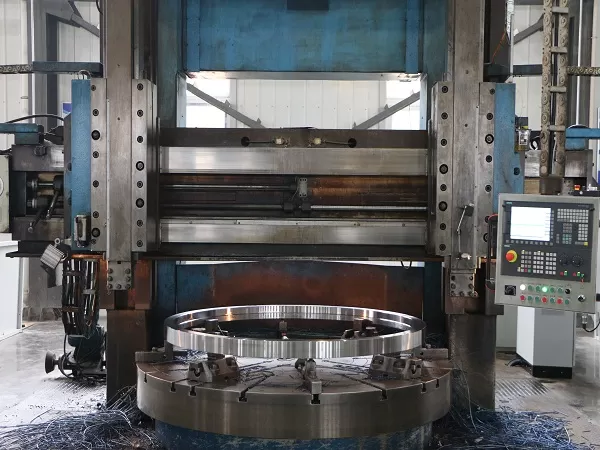

Processing Equipment

Certification

We always adhere to the industry's first-class quality control standards. By selecting industry-leading brand components and materials combined with advanced manufacturing processes, we ensure that each product has excellent reliability and durability. DAILIS products have obtained ISO9001 quality management system certification and CE safety certification.

News Events

Product Knowledge

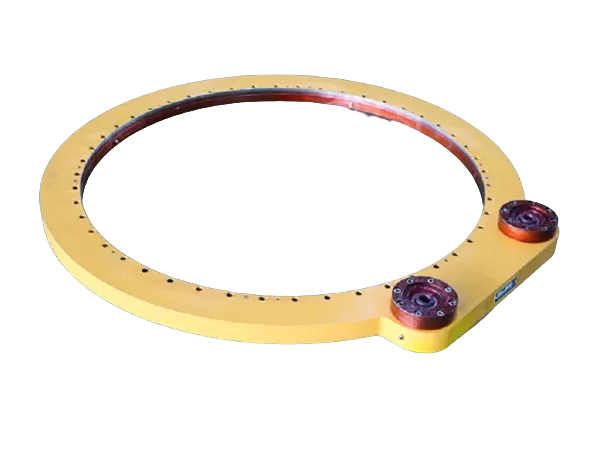

Spur Gear Slew Drives: Output Speed Range Based on Load Conditions

The output speed of Spur Gear Slew Drives is not a fixed value but is flexibly adjusted according to actual working load and operating conditions, which is a key feature that ensures the drive’s transmission efficiency and service life.

Protective Performance of Spur Gear Slew Drives

Spur Gear Slew Drives feature a structurally optimized design with customizable protective configurations, enabling them to adapt to various harsh working environments and maintain stable transmission performance. Their protective performance is mainly reflected in the following aspects

Compatibility of Spur Gear Slew Drives with Power Sources

Electric MotorsThis is the most common and mainstream matching power source. AC asynchronous motors, DC servo motors, and stepping motors can all be directly connected to the drive via a coupling or reducer adapter. It is particularly suitable for precision transmission scenarios such as automated production lines and CNC equipment, where it can leverage the high control accuracy of motors to achieve stable speed regulation and positioning.

Product Note: Lubricant Replacement Interval for Spur Gear Slew Drives

Normal Operating ConditionsFor standard industrial scenarios (temperature between -30°C and 50°C, medium load, 8-hour daily operation, and clean working environment), lubricant replacement is recommended every 6–12 months or after 2,000–3,000 operating hours, whichever comes first. This interval ensures that the gear meshing surface remains well-lubricated, reducing wear and maintaining transmission efficiency.

Spur Gear Slew Drives - Wide Temperature Adaptability for Stable Operation

Tailored to different operating environments, these drives can be paired with custom lubricants to ensure optimal functionality in extreme conditions. They maintain stable operation in temperatures ranging from -30°C to +50°C, adapting seamlessly to cold climates and high-heat working scenarios alike.

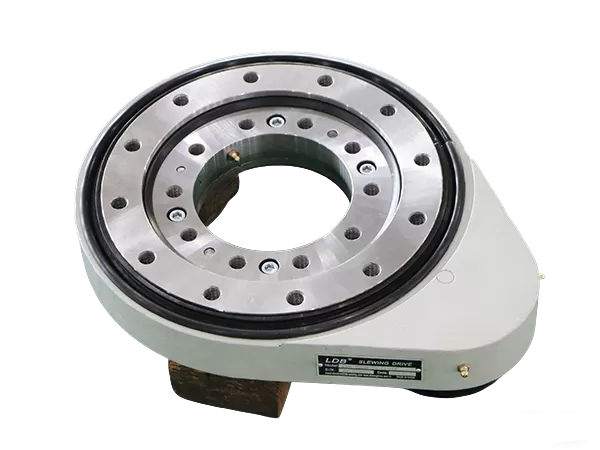

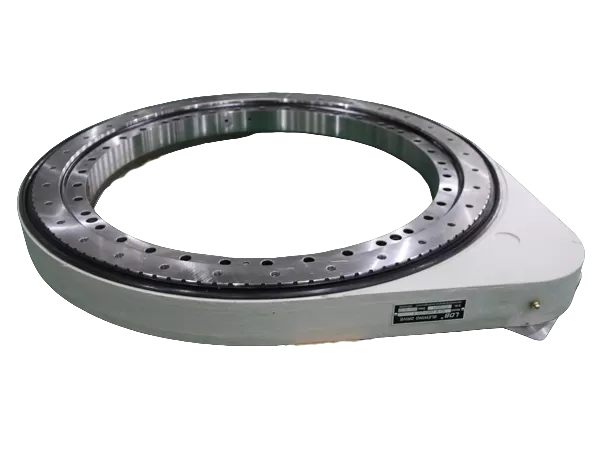

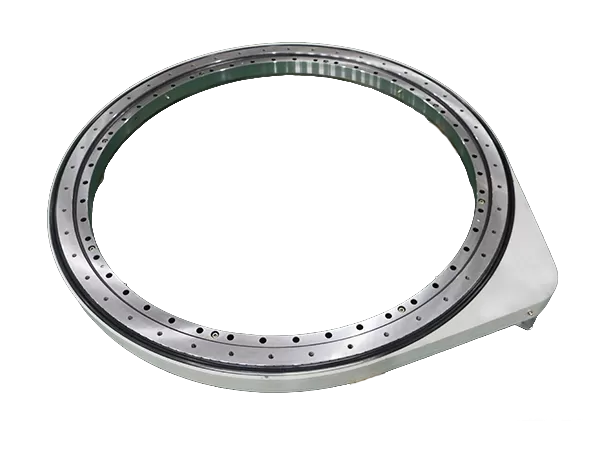

Differences in Mounting Adaptability and Flexible Customization Between Spur Gear Slew Drives and Slewing Drives

Mounting adaptability and customizable flexibility stand out as the core advantages of Spur Gear Slew Drives over slewing drives. Spur Gear Slew Drives can be flexibly tailored to specific installation conditions, whereas slewing drives feature relatively fixed mounting configurations with limited customization scope.

Differences in Precision Between Spur Gear Slew Drives and Slewing Drives

In contrast, slewing drives mostly adopt a composite transmission structure, which involves more gear meshing links. Errors in each link are prone to accumulation, leading to a decrease in overall transmission precision. In addition, slewing drives are often used in heavy-load scenarios; after long-term stress, gear wear is more likely to aggravate precision deviation, further widening the precision gap with Spur Gear Slew Drives.

Differences in Output Speed Between Spur Gear Slew Drives and Slewing Drives

Output speed is one of the most intuitive differences between spur gear slew drives and slewing drives. Thanks to the structural characteristics of their gear meshing, spur gear slew drives offer superior high-speed transmission capabilities, with output speeds significantly higher than those of slewing drives.